Download the White Paper describing how continuous aseptic freeze-drying can address the major pain points of pharmaceutical batch freeze-drying

News

The paradigm shift from batch to continuous manufacturing

After more than 50 years it is time for a paradigm shift.

We have created a White Paper describing how continuous aseptic freeze-drying can address the major pain points of pharmaceutical batch freeze-drying such as: time-consuming, inefficient, energy-consuming, and poorly controlled.

With a special case study from the company simAbs on the continuous manufacturing process that consistently produces high-quality Drug Substance of monoclonal antibodies.

Download by clicking the thumbnail below.

For the most up to date news, please follow us on LinkedIn via the link below

Download the White Paper on "Stabilizing mRNA LNPs via controlled, continuous freeze-drying"

News

Stabilizing mRNA LNPs via controlled, continuous freeze-drying

Lyophilization is considered to be one of the most promising approaches to stabilize mRNA-LNP formulations and enhance their stability at refrigerated or even room temperatures.

However, lyophilization is a slow, expensive, poorly controlled, and labor-intensive process. Consequently, these disadvantages hamper the fast and cost-efficient development of mRNA-LNP vaccines.

Download the White Paper describing the advantages associated with a RheaVita’s NextGen continuous and controlled lyophilization. This drying technology allows the R&D team and the MSAT team to save money and staffing. It opens a path for seamless scaling-out without the need to reformulate lyophilization protocols. All this may result in a faster time to the market for your mRNA drug or vaccine.

Download by clicking the thumbnail below.

For the most up to date news, please follow us on LinkedIn via the link below

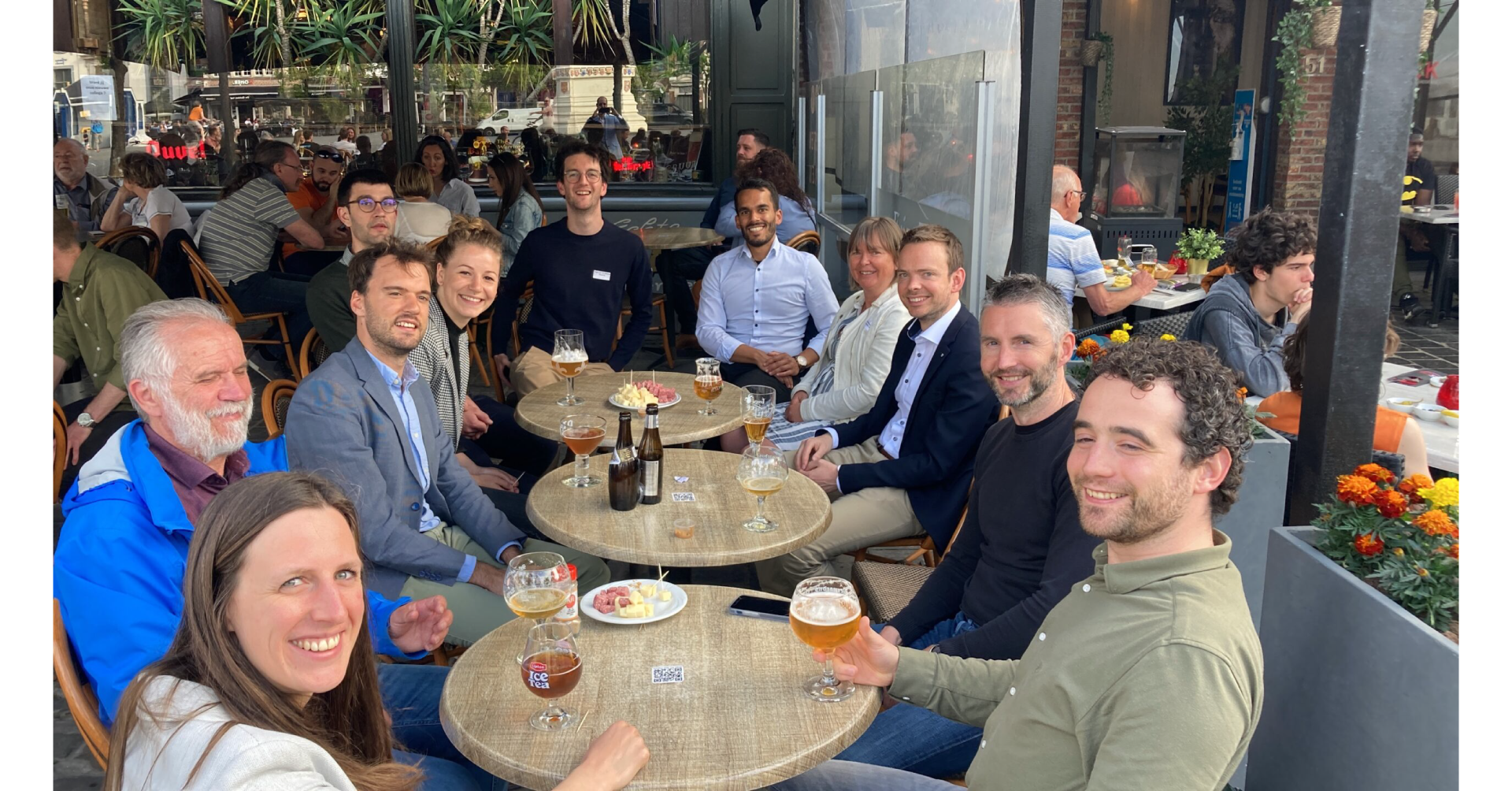

Top 20 global pharma players and RheaVita

Insights

Did you know RheaVita BV is working together with most of the top 20 global pharma players?

Would you also like to improve your freeze-drying processes?

Contact us at info@rheavita.com for more info

For the most up to date news, please follow us on LinkedIn via the link below

Instrument in the picture - The SVU

Insights

Are you looking to accelerate your process and formulation development tracks?

Do you have minimal drug product available?

You don’t have a lot of time but wish to complete a full DOE?

Do you wish to find and use the optimal freeze-drying temperatures?

All those questions and many more can be answered by using the SVU lab scale freeze-drying unit.

Used by ourselves to conduct all the feasibility studies, it can be used by any team looking to accelerate process and formulation development for freeze-dried products.

Reach out to us via info@rheavita.com if you wish to receive more info or download the brochure here: Brochure SVU

For the most up to date news, please follow us on LinkedIn via the link below

Development services available

Insights

Having trouble with formulation development of your biopharmaceutical product which requires freeze-drying?

Developing a suitable formulation to guarantee long-term stability of freeze-dried products can be challenging. A formulation needs to be optimized to withstand the dehydration stresses during a freeze-drying cycle. Furthermore, the formulation also has a direct impact upon the process performance.

At RheaVita, we have the in-house knowledge and experience to conduct and support the formulation and process development of your product. Our experts not only assess the impact upon the relevant critical quality attributes, but also immediately evaluate the impact upon the process performance.

For more information regarding the RheaVita formulation development and optimization services, please visit our services page or get in contact with our enthusiastic team of formulation specialists via info@rheavita.com.

For the most up to date news, please follow us on LinkedIn via the link below

Company movie

Insights

Presented poster on freeze-drying as a gene therapy stabilizer

A while ago our CEO Thomas De Beer was interviewed by Kanaal Z – Canal Z which lead to a short company movie that you can watch here: company movie.

Would you like to know even more about our technology, equipment or services, don’t hesitate to contact us via info@rheavita.com

For the most up to date news, please follow us on LinkedIn via the link below

Completion of 3-Day Freeze-Drying Course

Insights

Another successful event

We had a wonderful 3-day continuous pharmaceutical freeze-drying course.

Three days of networking, talks about PAT opportunities in continuous freeze-drying and some very interesting case-studies.

Looking forward to our next event about continuous freeze-drying in full compliance with GMP-guidelines in Q1 2023!

For the most up to date news, please follow us on LinkedIn via the link below

Upcoming Lyophilization Course

Insights

From Tuesday May 10th until Thursday May 12th 2022 our 3rd in person Lyo Course will take place in Ghent!

All info and how to register can be found on this page: 3rd Lyo Course.

For the most up to date news, please follow us on LinkedIn via the link below

Developing and scaling a freeze-dried formulation shouldn't be a time consuming hassle!

Insights

Presented poster on freeze-drying as a gene therapy stabilizer

The SVU (Single Vial Unit) is an ideal R&D instrument for ultra fast product and process development with very little material consumption.

It enables fast DOEs and is extremely flexible thanks to multiple parameter settings.

Next to that the process optimized on the SVU can easily be transferred to larger GMP scales.

Feel free to reach out to us in case you would like to know more or in case you have a lyophilization challenge.

For the most up to date news, please follow us on LinkedIn via the link below