PAT

Process Analytical Technologies (PAT)

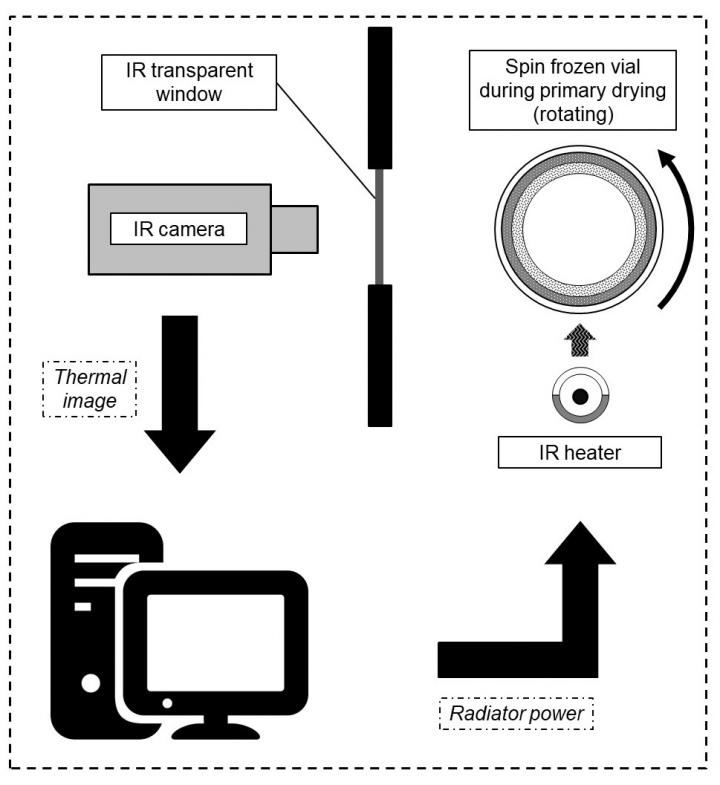

Process Analytical Technologies (PAT) for process monitoring and control of critical process and product parameters at the level of each individual vial (100% inspection) are an essential part of the RheaVita continuous freeze-drying technology. Several tools, such as near-infrared (NIR) Spectroscopy and thermal imaging are included. NIR spectroscopy provides detailed in-line information about several quality attributes like residual moisture content, protein conformation and the solid state of the product. It allows accurate detection of the endpoints of primary and secondary drying.

In turn, infrared (IR) thermography allows contactless, real-time and spatial monitoring of the product temperature at the sublimation interface during primary drying and of the product temperature during secondary drying, hence ensuring that the critical product temperatures during freeze-drying are never exceeded, leading to guaranteed product quality of all processed vials (Van Bockstal et al. , 2018, Analytical Chemistry, 90, 13591-13599). The implemented PAT sensors also provide feedback control to process settings. The power of the individual infrared heaters in the continuous drying modules is adapted to maximize the drying efficiency while staying under the critical temperature.

The implemented PAT strategy in the RheaVita continuous freeze-drying technology provides:

- Improved Quality Assurance – decreased defect levels – approaching zero

- Identical process conditions for each vial

- Process visualization methods (PAT) provide 100% unit monitoring, control, inspection

- Inherent high potential for real-time release from process understanding, control and 100% inspection