Our products

Scalable Freeze-Drying Solutions from R&D to GMP

RheaVita offers a range of freeze-dryer models covering R&D as well as GMP.

The RheaLyo™ PAT approach reduces tech transfer efforts significantly. With a high level of transferability, moving your drug product or vaccine through the lyophilization scaling process will save you time and money.

Get in touch for customized solutions or order a pre-engineering study for exploring the implementation of a RheaLyo™ GMP-Flex line in your facility.

Product range features

- Product name

- GMP?

- # Spin-freeze

positions - # Drying positions

- Estimated daily capacity

range (24h)

- RheaLyo™ Mono Freeze-Dryer

- No

- 1

- 1

- ≈1-6

- RheaLyo™ Multi Freeze-Dryer

- No

- 2

- 12

- ≈50-100

- RheaLyo™ GMP-Flex “4/120”

- Yes

- 4

- 120

- ≈620-1,610

- RheaLyo™ GMP-Flex “16/240”

- Yes

- 16

- 240

- ≈1,250-5,640

- RheaLyo™ GMP-Flex “24/600”

- Yes

- 24

- 600

- ≈3,130-9,670

RheaLyo™ Mono freeze-dryer

The RheaLyo™ Mono system accelerates R&D and formulation development through rapid, small-scale continuous freeze-drying.

Optimized processes are easily scaled for GMP production, significantly reducing tech transfer and time-to-market.

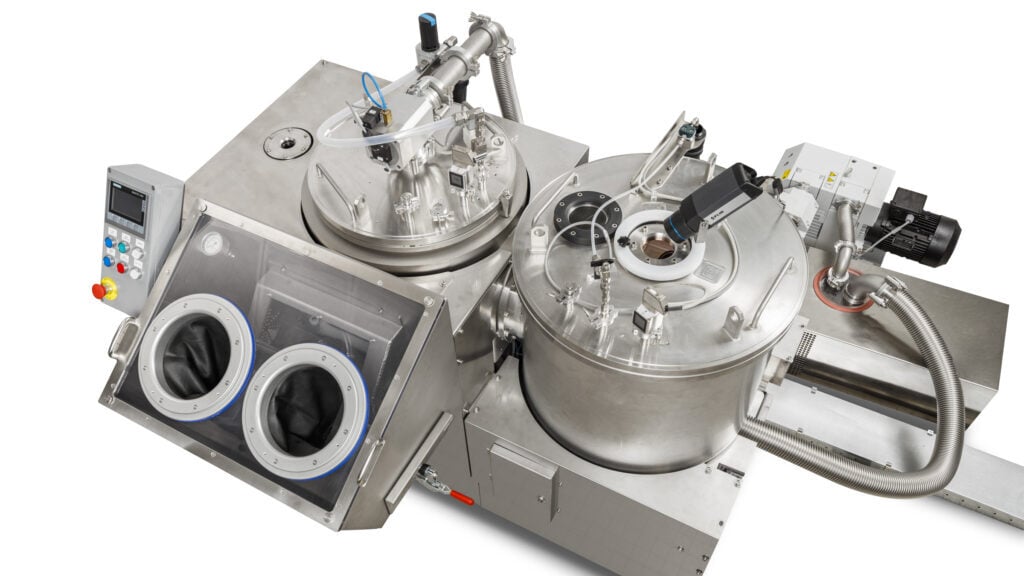

RheaLyo™ Multi freeze-dryer

The RheaLyo™ Multi system streamlines pre-clinical production with minimal tech transfer and direct scalability to GMP lines.

Advanced controls ensure pre-clinical quality closely matches future GMP runs.

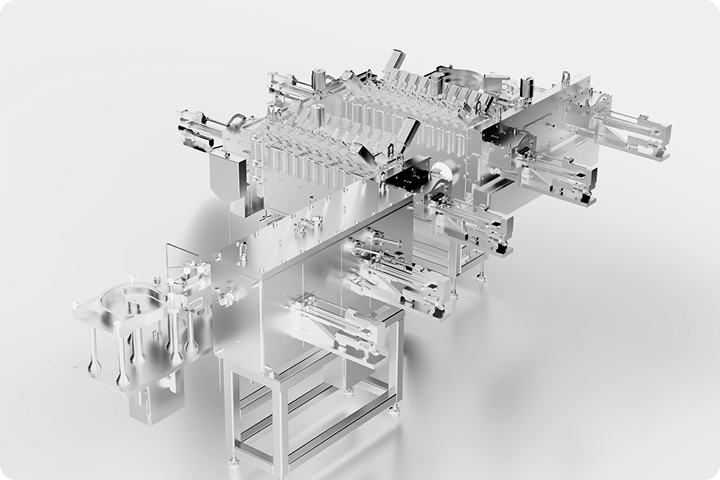

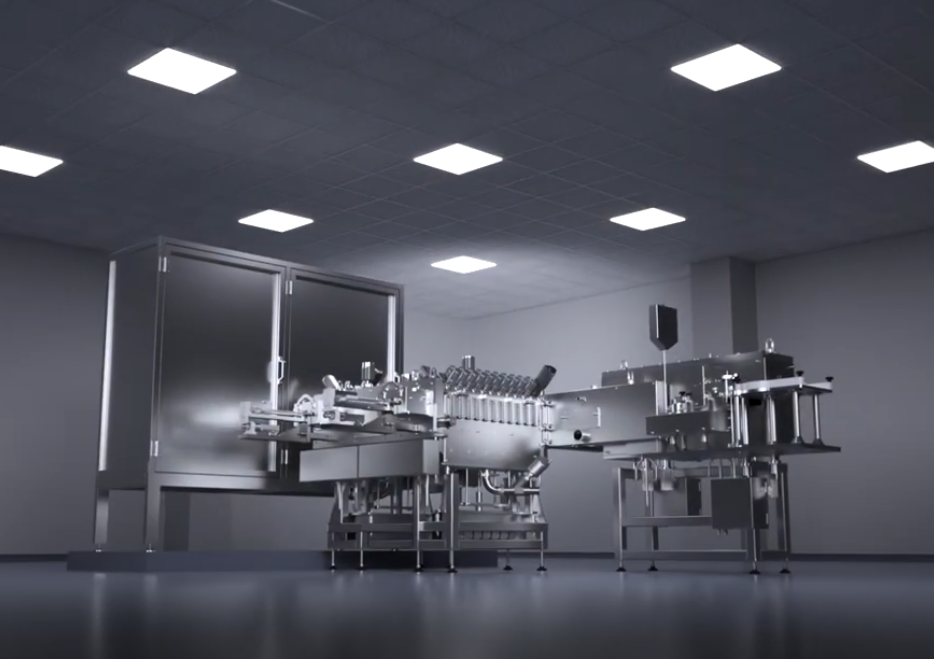

GMP-Flex continuous freeze-dryers

RheaLyo™ GMP-Flex is the only commercial continuous freeze-drying system for GMP pharmaceutical production.

Robotic automation ensures precise, high-capacity vial processing under controlled conditions.

Schedule a consultation with our experts to explore the best solutions for your needs.

Discover our services

RheaVita offers comprehensive continuous freeze‑drying services—from feasibility studies and formulation development to process optimization.